Hexa

Technology

Clean, local, and endlessly adaptable manufacturing.

From the Lab to the water

Our technology is developed and continuously refined by our engineering team in our Lab, just 1km from the ocean, a direct link between design and testing. Each prototype moves from controlled measurements to real conditions within hours.

HEXA® DNA:

Rigorous testing

To guarantee performance, we test our printed structures according to strict protocols:

01. Rigidity & controlled flex

Longitudinal flex testing to ensure predictable response under load.

→ Result: high rigidity, precisely tuned across the board, without unnecessary weight.

02. Torsion & directional stability

Torsion measurements to ensure clean energy transmission without energy loss.

→ Result: a more precise board, capable of holding its line in variable conditions.

03. Impact resistance

Instrumented impact tests on 3D hollow areas.

→ Result: superior absorption capacity, maintaining structural integrity and facilitating repairability.

04. Environmental tests

Validation in real conditions: thermal variations, humidity/drying cycles, prolonged immersion.

→ Result: lasting dimensional stability and controlled aging.

EACH PROTOCOL HAS A SINGLE OBJECTIVE:

LONG-TERM PERFORMANCE WITHOUT COMPROMISING RELIABILITY.

AN APPROACH WHERE ENGINEERING, DESIGN and performance come Together.

Our expertise spans design, CAD, large-scale 3D printing and innovative composite processes.

Each discipline operates within a single, integrated workflow, where geometry, materials and mechanics are deliberately calibrated. Our teams analyze forces, control densities and optimize internal structures to deliver predictable behavior on the water.

This integrated approach, from digital modeling to physical fabrication, allows us to engineer boards with measurable performance, consistent quality and durability shaped by precision rather than excess.

3D core

Architecture

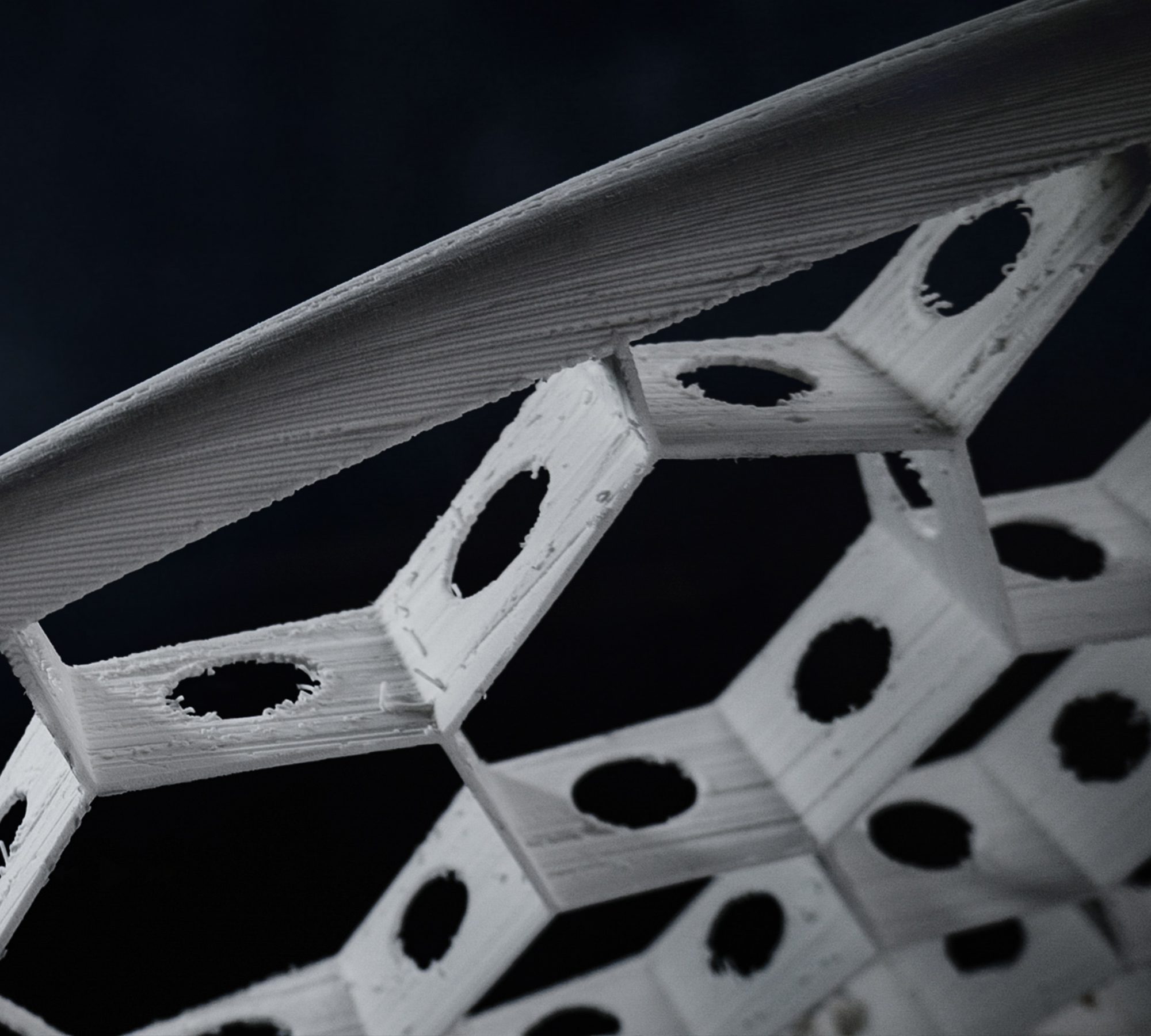

At the heart of each board, a 3D core with parametric hexagonal geometry governs the mechanics of the ride.

This architecture, printed layer by layer, enables precise local control of rigidity, flex, inertia and vibration absorption. By modulating cell density, we tune structural behavior, defining power or flex zones, optimizing energy transfer, and managing swing weight. This internal control unlocks a wide range of mechanical possibilities, tailored to the specific requirements of different brands (surf, kite, foil).

The result is a lightweight architecture that reduces the need for carbon reinforcements, while ensuring performance, industrial stability and optimized production costs.

3D-PRINTED CORE

A unique patented process that leverages 3D-printing and parametric design to offer endless mechanical possibilities.

Stiffness/flexibility, Weight, Vibration damping and Inertia of the boards can be mastered.

The technology combines a 3D-printed core and a unique composite shell.

The core contains more than 90% of bio-based content and the resin we use is made in France more than 50% bio-based.

HEXA Lab & Factory facility is based in Anglet, France.

We integrate design, prototyping and batch production relying on advanced technologies.

Our process shortens supply chains and cuts steps, enabling just-in-time production close to your market.

Surf, Kite, Foil -

Custom by design.

Our digital boardmaking lets us place stiffness, flex, and mass exactly where they matter. By controlling internal structures (infill geometry) we can raise or lower effective stiffness and shift swing-weight to change how a board initiates turns, stores/releases energy, and tracks at speed.

__ For foil boards, we target very high longitudinal and torsional stiffness so rider input transfers cleanly into speed and control.

__ For surfboards, we design purposeful flex windows that bend and spring back to project you out of turns, while managing swing-weight to balance drive and responsiveness.

__ For kite boards, we reinforce high-load zones so landings are supported and chop feels smoother, keeping the platform stiff where needed, yet comfortable over distance.

Key milestones

From the first prototypes to our earliest collaborations in kiteboarding and foiling, these milestones mark the evolution of HEXA.

2019

2020

2021

2023

2024

2025

2026

A CONSCIOUS LINE

As pioneers of conscious surfing, we chart our course where innovation goes hand in hand with preservation. From our first prototypes made from recycled materials to each board designed with tomorrow in mind, we are shaping the future with respect for life.

We devise increasingly bold and sustainable solutions.

Tech

Hexa®

Engineering

3D-printed core

We are pioneers

pushing what a board can do

Partnerships

Our partners are the proof and the point. We co-engineer products behind the scenes: they bring rider insight and design language; we bring process, advanced materials, and parametric/mechanical tuning, from pilot to scale.

That’s how brands turn tech into distinctive, high-end boards.

A tribute to Pioneers

Boards start with hands and lines of designers, shapers, riders. We honor that craft and extend it with digital precision: parametric design, advanced composites, and large scale 3D-printing that turn sketches into rideable reality. We are pioneers pushing what a board can do.

shapers, craftmen, designers, engineers

shapers, craftmen, designers, engineers